Live Project - New Build Rothbury, Northumberland

Richard and Ros purchased a site in the Northumberland town of Rothbury to build a unique, modern home that maximises the stunning views across the surrounding countryside. They collaborated on the initial concept design with their daughter, architect Helen Groves.

A key aspect of the design is to make the most of the views and optimise the building's orientation to increase natural sunlight. The house is designed to be constructed using SIPs (Structural Insulated Panels), which are manufactured off-site and then delivered and assembled on-site.

Combining a highly insulated building fabric with the latest technologies including MVHR (Mechanical Ventilation with Heat Recovery), an air source heat pump, and a standalone PV array the home achieves an A+ SAP rating.

To deliver this exceptional property, clients Richard and Ros, the main contractor Smailes Construction, and the Model Projects team have worked closely to ensure an efficient on-site programme.

Existing Site & Location

The site occupies a large south-facing slope with stunning panoramic views across the Northumberland countryside. Spanning approximately three acres, it currently features a 1970s bungalow, which will be demolished as part of the proposed works.

The landscape is characterised by natural vegetation, mature trees, and a rich variety of wildlife. Original dry stone walls and exposed rock formations remain in place, contributing to the site’s distinctly rural character. Despite its countryside setting, the site is within walking distance of Rothbury town centre, offering access to shops, pubs, and restaurants.

The proposed new house is positioned at the top of the site to take full advantage of the exceptional views. It is carefully cut into the slope, with a retaining wall used to support and shape the surrounding land. All excavated earth will be retained and sculpted on-site, creating a flowing garden that follows the natural topography.

Ground Works & Site Preparation

Before construction works could start extensive onsite earth movement was required to prepare the site for the new dwelling. The works included cut and fill to allow for both the retaining walls and the slab.

The house has been designed to sit on a reinforced raft foundation slab. Due to the natural rock a raft foundation is ideally suited for this type of scheme. An initial layer of hardcore was compacted down to create a level base. Rebar mesh was laid to the form and shape of the main house and garage. The slab was then poured in four phases.

The retaining wall is built from block work, sitting on a strip foundation reinforced with rebars.

The other major challenge onsite was the main drainage run, as the public sewer is located at the bottom of the site. Due to the steep slope a series of drop shaft manholes were required and surface water dealt with via large soakaways.

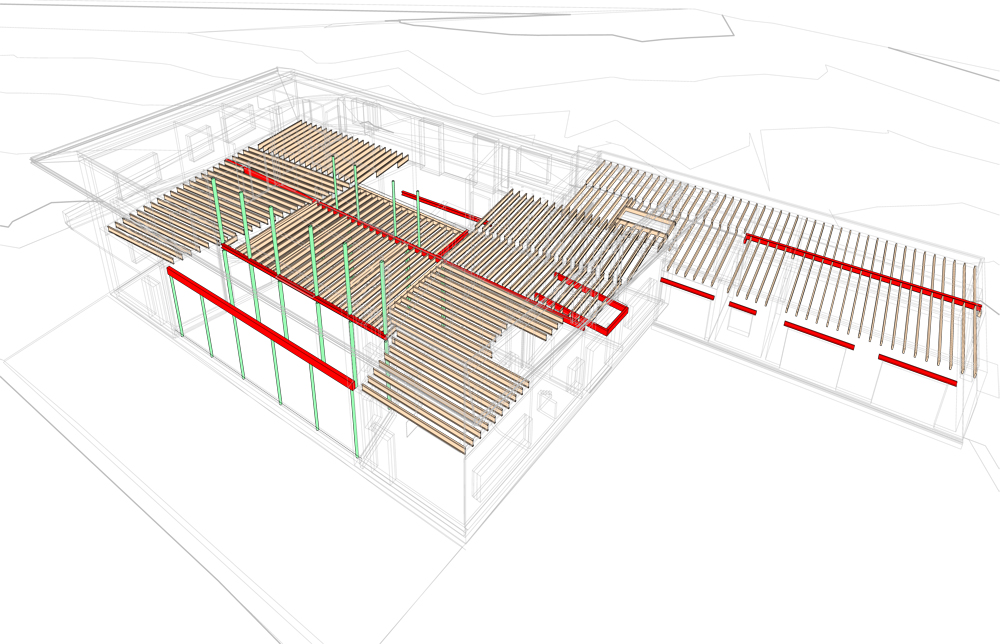

Sips Superstructure

Following the completion of the raft foundation, the next phase on site involved setting out the kicker brick course. This is a critical step in SIPs construction, as it establishes the precise footprint for the installation of the structural panels. Since the panels are prefabricated under controlled factory conditions, the kicker brick must be laid within tight millimetre tolerances to ensure a perfect fit.

This phase of work, which took five weeks, saw the full erection of the superstructure including the ground and first-floor walls, the structural first-floor deck, and the structural roof system, which comprises both purlins and SIPs panels. The panels used are Kingspan TEK, supplied by SIPS@Clays LLP.

To achieve the generous open-plan interior spaces, structural steel has been incorporated into the design. The integration of steel with the Kingspan TEK system and glulam beams was carefully considered to minimise cold bridging and maintain high thermal performance.

Structural Insulated Panels (SIPs) are a high-performance building system for residential and light commercial projects. Each panel consists of an insulating foam core sandwiched between two structural facings, typically oriented strand board (OSB).

SIPs are manufactured under factory-controlled conditions and can be tailored to nearly any building design. The result is a highly efficient, strong, and cost-effective building system. Building with SIPs reduces construction time, labour, and long-term energy costs.

External Finishes

Roof Finish

A standing seam metal roof has been specified for the main roof and the north-facing rear wall. Given the large roof area and long spans, material selection was critical. Pre-coated aluminium was chosen for its durability, clean aesthetic, and natural texture. As a flat-rolled product, it offers the precision and consistency required for such extensive surfaces.

Precoated aluminium is also used for all key roof elements, including the main roof covering, rear wall cladding, soffits, and fascia. The fascia is a prominent design feature, carefully detailed to form a bold C-section profile. Finished in a dark, natural tone to match the main roof and rear wall, the fascia contrasts subtly with the lighter grey soffit, creating a crisp, contemporary look.

Brickwork

The main house features a brick-faced exterior using standard-sized Bradgate Multi Cream bricks, chosen for their soft tonal variation and timeless aesthetic. The brickwork is tied back to the primary SIPs structure using specialist wall ties, with a 50mm air cavity to ensure proper ventilation and moisture management.

To achieve a clean, cohesive finish around the window and door openings, bespoke lintels incorporating brick slips have been used. These create a seamless brick surround that blends perfectly with the main façade, enhancing the overall architectural detail and visual consistency.

Windows & Doors

The windows and doors are aluminium-framed with a grey external finish, paired with white-painted timber internally for a warm, clean interior aesthetic.

A standout feature of the house is the three large curtain walls on the south-facing elevation. These include two curtain walls at ground floor level forming the inner and outer layers of the conservatory space and a third, single curtain wall serving the upper-floor living room. These expansive glazed elements maximise natural light and provide uninterrupted views of the surrounding landscape.

The front entrance is defined by a solid timber door, flanked by two full-height fixed sidelights, creating a striking and welcoming entryway.

Microgeneration and Sustainable Design

The design of the house embraces a holistic approach to sustainability from the use of advanced construction methods to the integration of microgeneration technologies. Pre-construction energy modelling indicates the property achieves an A+ SAP rating, a strong indicator of excellent energy performance. (SAP, or Standard Assessment Procedure, is the UK government's method for assessing a dwelling’s energy efficiency.)

Building Fabric

The first step in achieving a sustainable home is optimising the building fabric — from the superstructure to the windows and doors. The goal is to deliver a highly thermally efficient, airtight envelope. The use of SIPs (Structural Insulated Panels), combined with high-performance glazing, results in very low U-values across all major elements, reducing heat loss and improving overall energy efficiency.

In addition to the Kingspan TEK SIPs structure, the design includes:

High levels of insulation beneath the foundation slab

An additional 50mm of insulation to all external SIP walls

A further 80mm of insulation added to the underside of the SIP roof panels

Another important passive design feature is the large roof overhang on the south-facing elevation. This helps to reduce unwanted solar gain during the summer months, improving internal comfort and reducing the need for mechanical cooling.

MVHR & Airtightness

Due to the high level of airtightness achieved in the property, ensuring consistent and healthy airflow is essential. This is accomplished through the installation of a Mechanical Ventilation with Heat Recovery (MVHR) system. MVHR works by supplying fresh, filtered air into the home while simultaneously extracting stale, moist air from areas such as bathrooms and kitchens. Fresh air is distributed into living spaces such as bedrooms and living rooms.

To maintain energy efficiency, the system uses a heat exchanger to recover thermal energy from the outgoing stale air and transfer it to the incoming fresh air. This process improves internal climate control, enhances indoor air quality, and significantly reduces overall energy demand.

Microgeneration

Due to the high cost of installing a new gas connection and to future-proof the property, an alternative heating solution has been selected. Air Source Heat Pumps (ASHP) serve as the primary system for both space heating and domestic hot water. These pumps work by extracting heat from the outside air and transferring it indoors using the principle of vapour compression refrigeration. An internal thermal store is integrated into the system to provide immediate heating on demand for the occupants.

In addition, a photovoltaic (PV) solar array has been incorporated to supply onsite electricity. While the property remains connected to the national grid, onsite renewable generation helps reduce reliance on external energy sources and mitigates the impact of rising energy costs. The site’s large south-facing slope makes it ideally suited for a free-standing solar array, maximising solar gain and energy production.